Fax: 0086-535-6513072

Mobile & Whatsapp: 0086-18253591114

Email / Skype: info@vinsondrive.com

Address: No. 55-3, Zhichu Road, Zhifu District, Yantai City, Shandong China

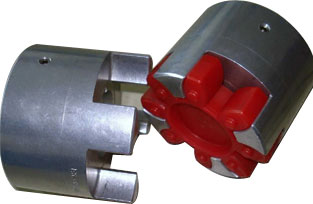

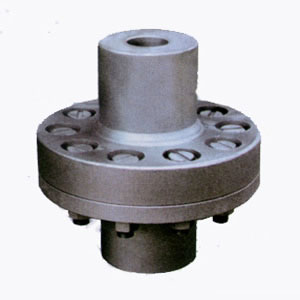

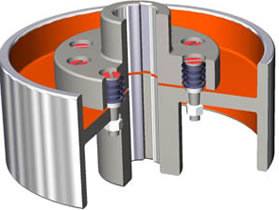

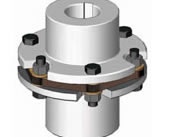

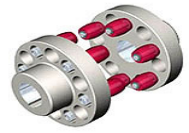

HL Type - Elastic Pin Coupling

● HL type - elastic pin coupling has been listed as the national standard GB5014-85, for a variety of mechanical coupling two coaxial axis of the drive shaft, usually used for frequent high and low speed movement. Working temperature of -20 ~ +80 ℃; transmission nominal torque of 40 ~ 20000N.m.

● Flexible pin coupling has a large structure is simple, reasonable, easy maintenance, two symmetrical interchangeable, long life, allowing a larger axial movement, with a buffer, shock absorption, wear and other properties.

● Shaft hole type has cylindrical (Y), conical (Z) and short cylindrical (J). Shaft hole and keyway according to the national standard GB3852-83 "coupling shaft and keyway form and size" of the provisions of processing. Semi-coupling using precision casting, cast iron HT20-40, cast steel ZG35 Ⅱ, shaft hole and keyway with drawing, the pin made of MC nylon b made.

● Elastic pin coupling is made of a number of non-metallic elastic material made of the pin, placed in the flange half of the coupling flange, through the pin to achieve the coupling of the two halves, the coupling structure is simple, Easy to manufacture, replace the replacement of flexible components more convenient, do not move the two halves coupling. The material of the elastic element (pin) is generally made of nylon, which has the ability to compensate for the offset of the two axes. The elastic part is cut and the working reliability is very poor. It is only applicable to the medium speed transmission shaft which is very low. In the work of high reliability requirements of the working conditions. HL type - flexible pin coupling basic parameters and the main dimensions

Size | Rated Torque Tn(N.m) | Allowable Rotating Speed [n]r/min | Axle Hole Dia. d 1 d 2 d z | Axle Hole Length | D | S | Rotary Inertia Kg.m 2 | Weight Kg | ||||

Y Type | Z, J 1, Z Type | |||||||||||

L | L 1 | L | ||||||||||

Iron | Iron | Steel | Iron | |||||||||

HL1 | 160 | 7100 | 12 14 | 12 14 | 32 | 27 | 32 | 90 | 2.5 | 0.0064 | 2 | |

16 18 | 16 18 | 42 | 30 | 42 | ||||||||

19 | 19 | |||||||||||

20 22 | 20 22 | 52 | 38 | 52 | ||||||||

24 |

| |||||||||||

HL2 | 315 | 5600 | 20 22 | 20 22 | 52 | 38 | 52 | 120 | 2.5 | 0.253 | 5 | |

24 | 24 | |||||||||||

25 28 | 25 28 | 62 | 44 | 62 | ||||||||

30 32 | 30 32 | 82 | 60 | 82 | ||||||||

35 |

| |||||||||||

HL3 | 630 | 5000 | 30 32 | 30 32 | 82 | 60 | 82 | 160 | 2.5 | 0.6 | 8 | |

35 38 | 35 38 | |||||||||||

40 42 | 40 42 | 112 | 84 | 112 | ||||||||

45 48 |

| |||||||||||

HL4 | 1250 | 4000 | 2800 | 40 42 | 40 42 | 112 | 84 | 112 | 195 | 3 | 3.4 | 22 |

45 48 | 45 48 | |||||||||||

50 55 | 50 55 | |||||||||||

56 | 56 | |||||||||||

60 63 |

| 142 | 107 | 142 | ||||||||

HL5 | 2000 | 3550 | 2500 | 50 55 | 50 55 | 112 | 84 | 112 | 220 | 3 | 5.4 | 30 |

56 | 56 | |||||||||||

60 63 | 60 63 | 142 | 107 | 142 | ||||||||

65 67 | 65 67 | |||||||||||

71 75 |

| |||||||||||

HL6 | 3150 | 2800 | 2100 | 60 63 | 60 63 | 142 | 107 | 142 | 280 | 4 | 15.6 | 53 |

65 70 | 65 70 | |||||||||||

71 75 | 71 75 | |||||||||||

80 | 80 | |||||||||||

85 |

| 172 | 132 | 172 | ||||||||

HL7 | 6300 | 2240 | 1700 | 70 71 | 70 71 | 142 | 107 | 142 | 320 | 4 | 41.1 | 98 |

75 | 75 | |||||||||||

80 85 | 80 85 | 172 | 132 | 172 | ||||||||

90 95 | 90 95 | |||||||||||

100 110 | 100 | 212 | 167 | 212 | ||||||||

HL8 | 10000 | 2120 | 1600 | 80 85 | 80 85 | 172 | 132 | 172 | 360 | 5 | 56.5 | 119 |

90 95 | 90 95 | |||||||||||

100 110 | 100 110 | 212 | 167 | 212 | ||||||||

120 125 |

| |||||||||||

HL9 | 16000 | 1800 | 1250 | 100 110 | 100 110 | 212 | 167 | 212 | 410 | 5 | 133.3 | 197 |

120 125 | 120 125 | |||||||||||

130 140 | 130 | 252 | 202 | 252 | ||||||||

HL10 | 25000 | 1560 | 1120 | 110 120 | 110 120 | 212 | 167 | 212 | 480 | 6 | 273.2 | 322 |

125 | 125 | |||||||||||

130 140 | 130 140 | 252 | 202 | 252 | ||||||||

150 | 150 | |||||||||||

160 170 | 160 | 302 | 242 | 302 | ||||||||

180 |

| |||||||||||

HL11 | 31500 | 1320 | 1000 | 130 140 | 130 140 | 252 | 202 | 252 | 540 | 6 | 555.7 | 520 |

150 | 150 | |||||||||||

160 170 | 160 170 | 302 | 242 | 302 | ||||||||

180 | 180 | |||||||||||

190 200 | 190 | 352 | 282 | 352 | ||||||||

220 |

| |||||||||||

HL12 | 63000 | 1250 | 950 | 160 170 | 160 170 | 302 | 242 | 302 | 630 | 7 | 902 | 714 |

180 | 180 | |||||||||||

190 200 | 190 200 | 352 | 282 | 352 | ||||||||

220 | 220 | |||||||||||

240 250 |

| 410 | 330 | - | ||||||||

260 |

| |||||||||||

HL13 | 100000 | 1120 | 850 | 190 200 | 190 200 | 352 | 282 | 352 | 710 | 8 | 1700 | 1057 |

220 | 220 | |||||||||||

240 250 | 240 250 | 410 | 330 | - | ||||||||

260 | 260 | |||||||||||

280 300 |

| 470 | 380 | - | ||||||||

HL14 | 160000 | 850 | 630 | 240 250 | 240 250 | 410 | 330 | - | 800 | 8 | 4318 | 1956 |

260 | 260 | |||||||||||

280 300 | 300 | 470 | 380 | - | ||||||||

320 |

| |||||||||||

340 |

| 550 | 450 | - | ||||||||

Main Coupling Types:

Star Elastic Coupling | ||

LX((XL) Star Elastic Coupling |

LXD(XLD) Flange Star Coupling |

LXS(XLS) Double Flange Star Elastic Coupling |

Column Elastic Sleeve Pin Coupling | ||

FCL Type Columnelastic Sleeve Pin Coupling |

Pump With Column Elastic Sleeve Pin Coupling |

LTZ Type (TLL) With Brake Wheel Column Elastic Sleeve Pin Coupling |

Diaphragm Coupling | ||

JMIJ Type Intermediate Shaft Type Diaphragm Coupling |

JM Ⅱ Type Without A Sink Hole Basic Diaphragm Coupling |

JMI Basic Diaphragm Coupling With Sink Hole |

Elastic Dowel Pin Shaft Coupling | ||

The HL Type - Elastic Dowel Pin Shaft Coupling |

ZL Type Coupling Type Elastic Dowel Pin |

HLL - Brake Wheel Elastic Dowel Pin Shaft Coupling |

Drum Type Coupling | ||

GIICLZ - Drum Type Coupling |

CL Type Coupling |

Rubber Coupling |

WGC Ⅱ Vertical Type Coupling |

GICL Type - Drum Type Coupling |

CLZ Type Coupling |

The Plum Flower Form Elastic Coupling | ||

Clampon Spline Torx Elastic Coupling |

LMZ -I (Original MLL - I) Split Type Brakewheel Quincunx Elastic Coupling |

ML1 Coupling |

The Rigid Coupling | ||

·YL Flange Coupling |

·YLD Type Flange Coupling |

GY, GYS, GYH Type Coupling |

Tyred Coupling | ||

UL Tyred Coupling |

LLB Metallurgical Equipment With Tyred Coupling |

LAK Saddle Piece Of Elastic Coupling |

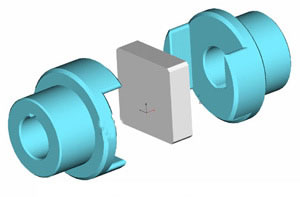

Oldham Coupling | ||

SL Oldham Coupling (Q/JL03-2001) |

Oldham Coupling | |

Universal Coupling | ||

SWP_B Type Has Stretched To Shorten The Type Universal Coupling |

SWP_E Telescopic Flange Long Universal Coupling |

SWC-WD Type No Telescopic Short Universal Coupling |

Snake-Like Spring Coupling | ||

JS Type Casing Radial Installation Type Coupling |

Snake-Like Spring Coupling | |

Water Pump Coupling | ||

·Sprocket Coupling |

Pump With Three Jaw Coupling | |

Industrial Expansion Sets Tight | ||

Z7C Type Bulging Tight Connection |

Z12A Type Bulging Tight Connection |

Z19A Type Bulging Tight Connection |

Prev :R Series Helical Gear Motor

Next :Three Phase AC Electric Motor